Guys,

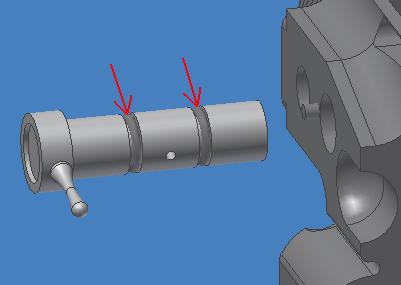

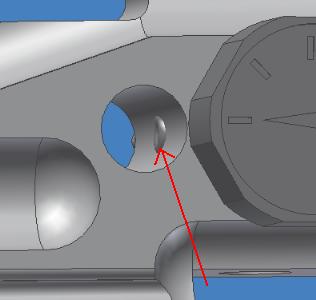

I just purchased a used max flow adjustable high pressure reg. I took the reg apart as soon as I received it because the seller had informed me that the on off did not work and needed o rings replaced. I took the reg apart and one by one replaced every o ring I could find with new ones. I noticed that on the on/off switch itself there are 2 o rings in line and I also noticed that there is one tiny o ring in the main chamber right near the on/off.

I was wondering if anyone familiar with the smart parts max flow regs knows which o rings would be responsible for the on/off functioning properly. Like I said in the title, the reg is pretty much set to ON at all times no matter where the on/off lever is turned. I would prefer NOT to leave my gun aired up 24/7 due to a non fucntional on/off switch on the reg. I was excited after putting the reg back together because I figured it would work with the new o rings...no such luck.

Any help will be greatly appreciated!

Nate

Reply With Quote

Reply With Quote