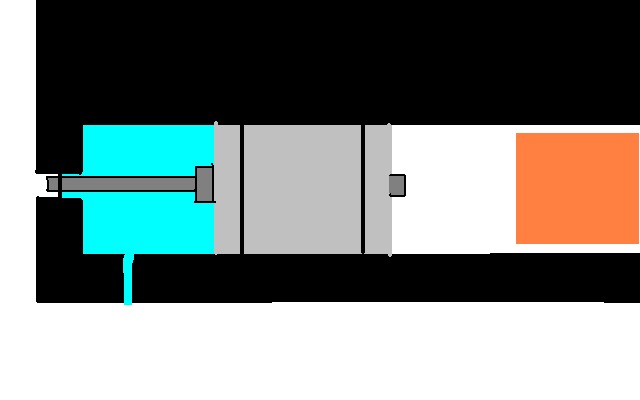

I'm designing my own airgun based on paintball parts, and I need a valve. I see no reason not to use a paintball valve; I want it to take 1000PSI and be able to handle CO2. It would be simple to use a valve that slides in and is anchored with a setscrew, like a Spyder valve, but Spyder valves leak gas back for blowback operation and I don't want that. I could use an autococker valve but machining threads for the lock screw into the body would be too hard. Can I anchor an Autococker valve with a setscrew from the bottom like a Spyder? Is there another type of valve? What do other non-blowback markers like Angels and whatnot use for valves?

By the way, why is it so dead here? I remember this place being really active.

Reply With Quote

Reply With Quote