Lets try thin again.

Rules: Stay on topic and no flaming

Well i have a feeling Renie and I were thinking along the same lines at the same time. lolI have been wanting to do this for almost a year now and thanks to him it may become a reality. I also have permission from him to post this.

Some have suguested this design could get pinched but seriously it is a coppy of another reg in a new housing. This reg was the template as it is simple and the parts are easy to get.

The point is to get something that will relocate the LPR from under the barrel or off the side of the asa to the forgrip and not look like an LPR.

This was my first idea

Now that looks good for what i used it for but wont work for an Ego Mag.

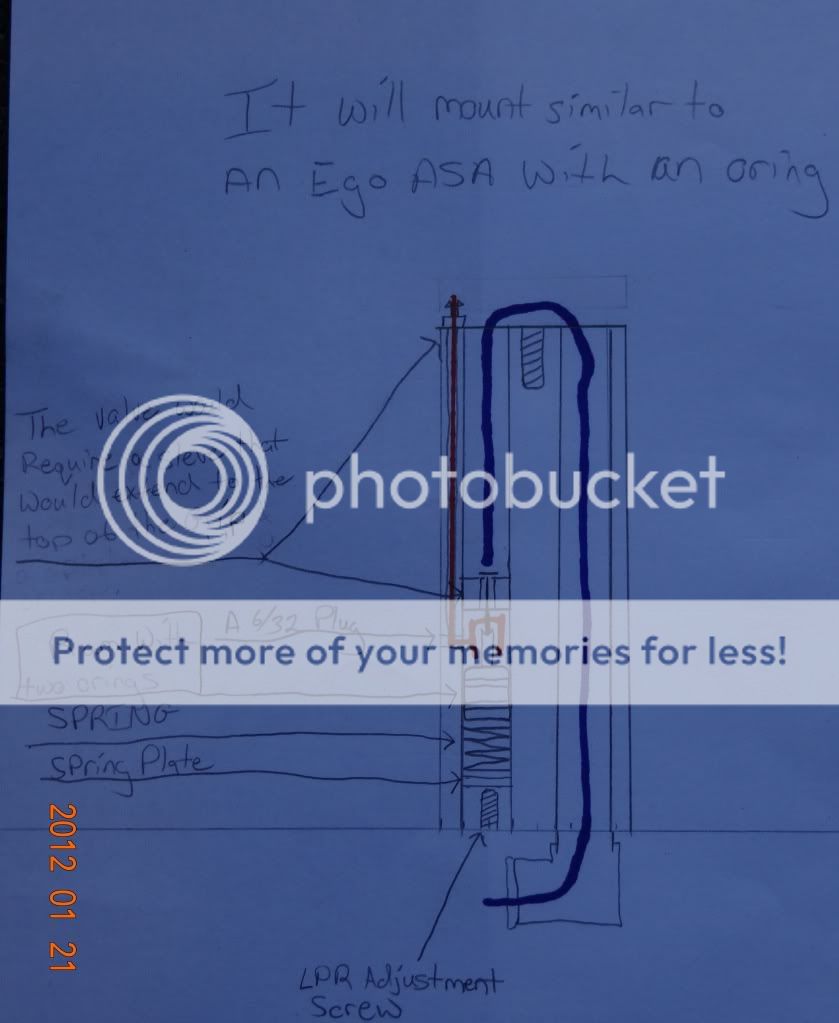

So I sketched this out using the internals from above.

Then the newest member to the Mag modding comunity, "Renie" privided this ruf cad to shw it is possible.He may be new here but the force is strong with this one. hehe

Any thoughts on the design or any other ideas are welcome. I considered using a Matrix LPR and designing it to just accept one of those, but think the parts I selected will be around and available longer than PPS.

Reply With Quote

Reply With Quote

I would increase the thicknesses a bit though to be safe.

I would increase the thicknesses a bit though to be safe.

It shoots plenty fast enough to.

It shoots plenty fast enough to.